INDUSTRY

My industrial experience include

-

Problems evaluation in production lines of different automotive plants, including fault detection, deficiencies and proposal of training plans for their respective solution.

-

Development and management of engineering projects for different companies.

-

Engineer consultant for several companies about assemble processes and vision inspection in quality processes.

Industrial training

I am Certified instructor by STPS (Secretaría del Trabajo y Previsión Social) in the following industrial courses as part of Introid:

Click below for more details

Given industrial trainins

August 2018

COGNEX Vision Systems. APTIV, Ramos Arizpe, Coahuila. Given to production and maintenance engineers

August 2018

COGNEX Vision Systems. INTROID INC. S.A. DE C.V., Ramos Arizpe, Coahuila. Given to engineers of different Companies

June 2017

Speed Control of Three phases induction motor. FLAMBEAU PLASTICS S.A. DE C.V, Saltillo plant. Given to maintenance engineers

April 2017

FANUC robot rogramming.

CHRYSLER ENGINE PLANT, Saltillo, México. Given to production engineers and supervisors.

March 2017

FANUC robot rogramming.

CHRYSLER ENGINE PLANT, Saltillo, México. Given to production engineers and supervisors.

April 2017

FANUC robot rogramming.

CHRYSLER ENGINE PLANT, Saltillo, México. Given to production engineers and supervisors.

November 2016

OMRON PLC programming.

FLAMBEAU PLASTICS S.A. DE C.V, Saltillo plant. (Co-instructor). Given to maintenance engineers.

August 2016

LabVIEW programming and PID control. RASSINI S.A. DE C.V, PIEDRAS NEGRAS PLANT. Given to production supervisors and instrumentation engineers

November 2016

Design of Experiments with minitab.

CHRYSLER ENGINE PLANT, Saltillo, México. Given to production engineers and supervisors.

March 2015

Design of Experiments with minitab.

CHRYSLER ENGINE PLANT, Saltillo, México. Given to production engineers and supervisors.

COGNEX VISION SYSTEMS

Companies

Training topics

Module I

-

Introduction to vision systems

-

Vision systems components selection

-

In-sight Explorer environment

-

Initial set-up

-

Connections

-

Image configuration

-

Scale assignment

-

Module III

-

Camera connections

-

Outputs configuration

-

Backups

-

Run jobs

Module II

-

Tools configuration

-

Locate Part

-

Patmax Patterns (1-10)

-

Edge

-

Blob

-

Circle

-

-

Inspect Part

-

Presence/Absence Tools

-

Brightness

-

blob

-

-

Measurement Tools

-

Distance

-

Blob Area

-

Circle diameter

-

Circle Concentricity

-

-

Measure Radius

-

Counting tools

-

Blobs

-

Patterns

-

-

Identification Tools

-

Read 2D code

-

Read Text (OCRMax)

-

-

Math & Logic Tools

-

-

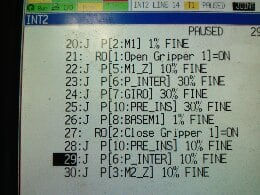

FANUC ROBOT PROGRAMMING

Companies

Training topics

Module I

-

Industrial robotics overview

-

Type of joints

-

Roboguide software installation

-

Teach pendant description

-

Robot arm motions

-

Joint

-

XYZ World

-

XYZ User

-

XYZ JOGFRM

-

TOOL

-

-

Tool configuration

-

TCP

-

Type of tool

-

Simple tool

-

Complex tool

-

-

Configuration methods

-

Direct entry method

-

3 Points method

-

6 Point method

-

Activate defined tool

-

-

-

User frame configuration

-

Methods of configuration

-

Direct entry method

-

3 Points method

-

4 Point method

-

Activate defined User frame

-

Module II

-

Create a program

-

Trajectories generation

-

Point set up

-

Type of motion towards a point

-

Type of points

-

Velocity configuration

-

Accuracy

-

Configuration options

-

-

-

Run program

-

Edition window

-

Edition options

-

Register a default position

-

Modify a position

-

Edit commands

-

Insert

-

Delete

-

Copy

-

Find

-

Remplace

-

Renumber

-

Comment

-

Undo

-

-

-

TPE instructions

-

Edit options

-

Registers R [ ]

-

Position Registers PR [ ]

-

Data variation with R [ ] and PR [ ]

-

Input-Output instructions

-

No-conditional jumps

-

Labels

-

Program calls

-

-

Conditional jumps

-

If

-

Select

-

-

Waiting instructions

-

Timers

-

Wait for true conditions

-

-

Complex trajectory generation

-

Module III

LabVIEW programming

Companies

Training topics

-

LabVIEW overview

-

LabVIEW environment

-

Block diagram and front panel

-

Flow programming

-

SubVI

-

Type of data

-

Clusters

-

Programming structures

-

For Loop

-

Case Structure

-

Flat Sequence

-

shift Register

-

While Loop

-

-

Formula Node

-

Arrays manipulation

-

Saving data in files

-

Debugging errors

-

State machines

-

Control systems

-

Final exercise: Monitoring and PID control of a temperature system using state machines

-

Problem Statement

-

Using programming structures: While, Case structure, Shift register, For loop.

-

Manipulation arrays

-

Input-Output handling

-

Debugging

-

DESIGN OF EXPERIMENTS

Companies

Training topics

Instituto Tecnológico Superior Alamo Temapache

-

Introduction

-

Process concept

-

Factor

-

Type of factors

-

Level

-

-

-

Experiments with one factor: Analysis of variance (ANOVA)

-

Design 2^2

-

Design 2^2

-

Analysis of results

-

Normal effects

-

Factorial plots

-

Main effects plot

-

Interaction plot

-

Cube plot

-

-

-

Response optimizer

-

Individual desirability

-

Composite desirability

-

Optimizing more than one output

-

-

Mixed factorial designs

-

Fractional factorial designs

-

Plackett-Burman design

THREE PHASES MOTORS CONTROL

Companies

Training topics

-

Introduction

-

Characteristic curves

-

Connections (Star triangle)

-

6 tips

-

9 tips

-

12 tips

-

-

Control of three-phase motors with Driver, Reliance Electric (MD65)

-

Control terminals block

-

Command screen

-

Commands description

-

Connections

-

Initial parameters setting

-

Frequency ranges setting

-

Control by external signal

-

Run and stop by external signals

-

Run and stop with interlock

-

Rotation direction change

-

Rotation direction change with internal interlock

-

Preset frequencies

-

Timers

-

Counters

-

Change between preset frequencies through conditional jumps

-

OMRON PLC Programming

Companies

Program

-

Introduction

-

General concepts

-

Boolean algebra

-

-

Connections

-

CX programmer

-

Development environtment

-

Initial configuration

-

First programm

-

Handling inputs and outputs

-

-

Ladder programming

-

Basic intructions

-

Relay functions

-

Set/reset functions

-

blocks functions

-

virtual memories

-

-

Counting Instructions

-

Internal Relays

-

Timing Instructions

-

JMP Conditional Jumps

-

KEEP interlock functions

-

Compilation of programs

-

Backups